Wrench Guide: How to Make the Right Choice

- Gray Tools Official Blog

- 04 Jan, 2024

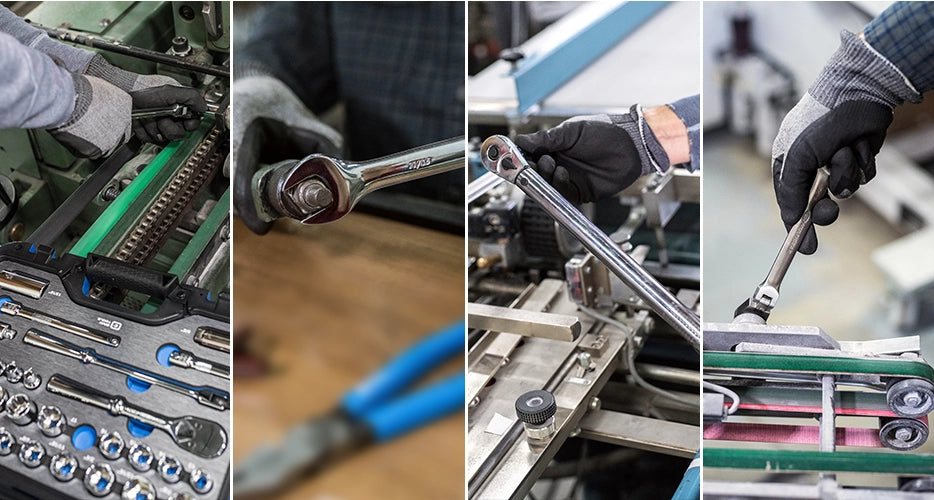

In the array of hand tools available to tackle any task, wrenches stand out as indispensable items within the toolkit. Whether you're a seasoned professional in the trade or a passionate DIY enthusiast, having an understanding of the various wrench types is important for making informed choices when it comes to selecting the appropriate wrench for the project at hand.

From adjustable wrenches to socket wrenches, each variant boasts distinct features and applications. Let's delve into the primary distinctions to aid you in selecting the optimal tool for your needs.

Combination Wrenches

Design and functionality: Combination wrenches feature both an open end and a closed end (ring) on the same tool, providing versatility for general-purpose tasks. The open end is typically set at a different angle than the closed end, allowing flexibility in various applications. Different sizes and lengths make combination wrenches to preferred tool in a variety of projects.

Uses: Ideal for diverse tasks, combination wrenches offer a secure grip for applying greater force with the closed end, and quick application and removal with the open end. While versatile, they may not match the efficiency of specialized wrenches.

Box-End Wrenches

Design and functionality: Box-end wrenches feature a closed-end design for a strong grip on fasteners, ensuring stability in demanding applications. The closed-box design enhances contact points with the fastener, reducing the risk of rounding off edges.

Uses: Well-suited for higher torque applications, box-end wrenches are less prone to slipping compared to their open-end counterparts. However, their utility may be limited in tight spaces due to the enclosed design.

Open-End Wrenches

Design and Functionality: Featuring U-shaped ends for swift application and removal, open-end wrenches excel in tight spaces where a full rotation is challenging.

Uses: Efficient in situations where a full circular motion is not possible, open-end wrenches are ideal for confined spaces. Caution is necessary to prevent rounding off bolt edges during use.

Ratcheting Wrenches

Design and Functionality: Ratcheting wrenches incorporate a ratcheting mechanism at the boxed end, enabling continuous force application in one direction without wrench repositioning. Available in various styles, such as double-boxed end, combination, and flex head, these wrenches mirror traditional functionality with the added convenience of the ratcheting mechanism.

Uses: Ideal for tight spaces where traditional wrenches may lack maneuverability, ratcheting wrenches allow you to keep the wrench in place while fastening. The optional switch permits a change in ratcheting direction without flipping the wrench. While excellent for loosening and tightening fasteners, caution is advised against using them to break fasteners loose, as it may damage the ratcheting mechanism.

Socket Wrenches

Design and functionality: Socket wrenches utilize interchangeable sockets on a ratcheting mechanism. With a variety of sizes available, they offer a secure grip and adaptability for different bolt heads. Various socket styles cater to diverse job requirements.

Uses: Socket wrenches excel in high-torque applications, such as automotive repairs. Their ratcheting mechanism facilitates efficient use in confined spaces, and the array of socket sizes makes them versatile for a wide range of tasks.

Torque Wrenches

Design and Functionality: Torque wrenches are specifically designed to apply a predetermined amount of torque to a fastener, ensuring precision in critical tasks. They come in various types, including dial-type, click-type, and electronic torque wrenches.

Uses: Essential for projects requiring precise torque, such as automotive work, torque wrenches are indispensable for those who prioritize accuracy. Click-type wrenches emit an audible click when the desired torque is reached, while dial-type wrenches rely on a visual scale for indication. Electronic torque wrenches offer digital precision and may include additional features like memory storage.

Crowfoot Wrenches

Design and Functionality: Crowfoot wrenches feature an open-ended design with a head shaped like a crow's foot, intended for reaching challenging-to-access fasteners.

Uses: Perfect for tight areas, crowfoot wrenches are typically used in conjunction with a torque wrench. They excel in reaching fasteners in spaces where traditional wrenches may struggle.

Adjustable Wrenches

Design and Functionality: Adjustable wrenches feature a movable jaw, allowing adaptation to different nut and bolt sizes. They come in various sizes, with some models featuring a built-in scale to gauge jaw width.

Uses: Versatility defines adjustable wrenches, making them suitable for tasks involving multiple fastener sizes. However, they may lack the precision fit of fixed-size wrenches and are not recommended for high-torque applications.

Pipe Wrenches

Design and Functionality: Pipe wrenches feature serrated jaws for a firm grip on pipes and rounded objects.

Uses: Primarily used in plumbing, these wrenches also prove useful in various applications requiring a secure grip on cylindrical objects. The adjustable jaw size accommodates different pipe diameters.

The following table provides a summary of the most suitable wrench based on specific requirements:

Selecting the appropriate wrench style for the task requires considering factors such as fastener size, space constraints, and the required torque level. Once you've narrowed down the list of compatible wrenches, you can make an informed decision on the tool that will efficiently complete the job. Investing in a diverse set of high-quality wrenches ensures you're well-prepared for any challenge that may arise.