Hand Punches and Chisels - A Complete Guide

- Gray Tools Official Blog

- 02 Mar, 2016

Punches and chisels have been in use for centuries. In fact, next to striking tools they are likely the oldest tools in the history of humanity.

In prehistoric times these tools were used for performing survival tasks such as carving wood, forming stone, and preparing and fabricating clothing.

Today hand held punches and chisels are used for removing pins and bushings, and cutting or splitting steel objects.

The words punch and chisel are often used generically; a close examination shows there are many types, shapes, designs and specific functions for these tools.

In this article, we will explore the different kinds available on the market today.

Punches

Punches can be classified into two distinct types: hollow and solid.

Hollow punches are designed to puncture a surface, such as sheet metal or leather in order to create a hole. A hollow punch is easily identified by its "exit hole" located near the working end. The exit hole allows the punched material to be removed and discarded.

The working end can vary in shape and size depending on the hole required and the material being pierced. To protect the working end, it is recommended that a board made of either wood or plastic be placed between work surface and material being pierced. This board should be strong enough to protect the work surface and yet soft enough to prevent the working end from being damaged.

Solid punches are one-piece rod-shaped tools made of metal designed to be struck by a hammer. They are typically used to drive objects such as pins or to form impressions on a work piece.

Solid punches can vary in diameter, length and tip depending on the job to be performed. Below is a brief description and characteristics of the most common solid punches.

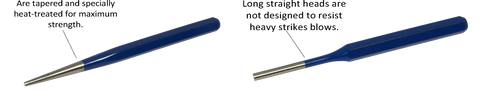

Pin Punches-used to drive or remove pins, after been loosened by a taper punch.

Pin punches feature a long head the same diameter as the tip and meant for removing tension or solid pins. Care must be taken when selecting a pin punch.

The ideal size for a given project is one where the tip is smaller than the encasing hole yet large enough to make solid contact with the pin to be removed or driven.

Pilot Punches-also, known as roll pin punches, they are designed to drive or remove hollow tension pins, such as tapered & rolled or solid pins.

They feature a similar long head like a pin punch with the difference being that they have slight bump at the tip permitting insertion into a rolled pin.

Taper Punches-designed for loosening and driving pins. Taper punches can also be used to align existing holes in two or more work pieces prior to bolting or riveting.

Centre Punches-used to make a mark on a material where a hole will be drilled. When struck, a small indentation is made in the work piece.

The indentation allows a drill bit to pierce the material more easily, while preventing bit walking and possible marring of the work piece.

Prick Punches-essentially the same as the center punch only it is designed for use on soft materials such as wood, plastics, and thin sheet metal. Can also be used to scribe marking lines prior to cutting or riveting.

Aligning Punches-used to align two or more holes in order to permit the insertion of a fastener. Their tapered body shape allows holes to easily be gathered and aligned as the punch is inserted. This punch is not meant to be struck and therefore not recommended for driving pins, rivets, or bolts.

Using the correct punch style for the application goes a long way in maintaining its useful life.

The most common mistake mechanics make is grabbing a pin punch to break loose a pin when the proper tool to use would be a tapered punch.

A tapered punch is specifically designed to take the heavy pounding needed to loosen pins.

Using a pin punch to start the initial removal can damage punch and the part being driven. The result is reduced productivity and increased risk to personal safety.

The correct approach for breaking a pin loose is to start with a taper punch then switch to the pin punch to complete the removal.

For this reason, it is highly recommended that mechanics have a matching tapered punch for every pin punch in their toolbox.

Chisels

Like punches, hand tool chisels can be also classified into distinct types: wood, masonry, and metalworking.

For the purposes of this article we will focus on the metalworking chisels. Once again, similar to solid punches, metalworking chisels are one-piece rod shaped tools made of metal designed to be struck by a hammer.They are primarily used to cut or shape metal.

Below is a brief description and characteristics of the most common chisels.

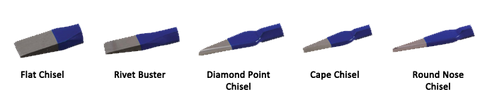

Flat Chisels-the most common of all the metalworking chisels. Often also referred to as cold chisels. Flat chisels feature a flat wide tip (working end) with a cutting edge. The size of the chisel is determined by the width of the tip. Common uses for a flat chisel are breaking chain, removing burrs, and cutting bolts.

Rivet Buster Chisels-share the same characteristics as flat chisels with the exception that the cutting edge is offset not centred. The offset design allows the chisel to lay flat and easily slide under the rivet to be removed.

Diamond-Point Chisels-Get their name from the distinct diamond shaped point. Are designed to punch holes and make V-shaped grooves in sheet steel.

Cape Chisels-feature a narrower cutting edge than flat chisels. Cape chisels are designed to square rounded corners in grooves or cut new grooves with square edges in steel.

Round Nose Chisels-similar to cape chisels, except instead of a straight edge they have a round edge on one side. The round edge allows them to cut grooves with round bottoms.

When used properly metalworking chisels are extremely useful for cutting steel objects and materials.

An important consideration when using any metalworking chisel is to be sure the object(s) being cut or worked is NOT harder than the chisel itself. Otherwise, the chisel’s point will dull or be destroyed.

If that happens, the best way to re-sharpen the chisel is to re-file the cutting edge using a hand file, not a grinder. Using a grinder could result in the chisel losing its temper.

Additional usage considerations include:

- Ensuring that head diameter of the hammer is never more than 3/8" larger than head of chisel or punch.

- Always use a proper punch or chisel holder. NEVER USE A PAIR OF LOCKING PLIERS as they will create sharp indentations that can endanger a user's hands when handling later on.

- Always wear safety goggles.

Proper Maintenance of Punches and Chisels

Routine maintenance is a very important step in ensuring a long useful life of your punch and chisel.

As striking tools, most punches and chisels are deferentially tempered. That means the striking end is softer than the working end.

As such when any punch or chisel mushrooms on the striking end, it must be dressed to prevent the mushrooming pieces from chipping off and causing harm.

Conversely at the opposite end (working end) maintaining a sharp and clean edge ensures you a have tool that is safe and ready to complete a job properly.

Things Look For When Buying Your Next Punch or Chisel

It wise to consider the steel used as punches and chisels can be made from a variety of different steels each varying in strength and reliability.

A punch or chisel made from premium tool steel and optimally tempered will deliver a tool that has working end that maintains its edge and shape longer and has a striking end that is hard enough to be struck without chipping or cracking.

Additional thoughts:

- Consider what is being cut or driven and determine the diameters, sizes and shapes needed to complete the project

- If you are working in or near sparking working environments consider punches and chisels made of brass, copper beryllium or aluminum bronze.

Does anyone make Chisels & Punches out of B-Grade steel like the hammers?

Good article. Can you tell me how to clean leather debris from a hollow prong multiprong punch?

VERY INFORMATIVE ARTICLE.

I NEED TO KNOW ABOUT THE DESIGN CONSIDERATIONS IN DESIGNING THE STRIKING HEAD OF THE CHISEL. WEATHER IT SHOULD BE THICKER THAN THE TOOL DIAMETER OR IT CAN BE THINNER KEEPING AWAY THE CONSIDERATION OF STRIKING HAMMER DIAMETER SHOULD BE MORE THAN THE THE STRUCK HEAD.

Great Article. You fellows did a fine job. I did not know you had hole punches. They look like high quality

Great article its nice to see a proper explanation of tools, particularly from an informed source like Gray Tools Thanks Jeff